Valveless Autowash Gravity (VAG) Filter

- For filtration of potable and process water.

- Gets backwashed automatically.

- Does not require any electricity or valves for operation and backwash.

- Reduces capital cost, operation cost and space in comparison to conventional Sand and Rapid

Gravity Filters.

- Range: 6 m³/hr. to 640 m³/hr. (with single unit).

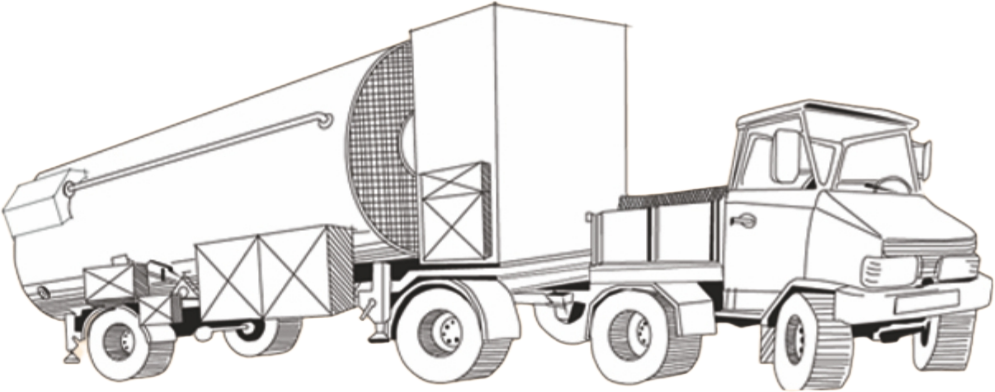

Mobile Water Treatment Plant

- Mobile Water Treatment Plant incorporates sedimentation, dosing, flocculation and filtration

all in one unit.

- Does not require any electricity.

- Flow: Upto 18 m³/hr.

2. Water Treatment Solution

SEWAGE TREATMENT PLANT (STP)

- Sewage is the wastewater coming from household, domestic and commercial outputs.

- They contain excreta of humans, animals, rainwater, and debris from sewers in them.

- It contains more solid waste due to the presence of such material in it and is more harmful

to human use.

- STP's uses operations like screening, sedimentation, scrapping, aerobic biology, fixed-film

or suspended growth treatment, air blowers, etc. to treat.

- APPLICATION AREAS: Used in community, real estate's, industries, hospitals & township

projects.

EFFLUENT TREATMENT PLANT (ETP)

- Effluent Treatment Plants or (ETPs) are used by leading companies in the pharmaceuticals,

Power, fertilizer and chemical industry to purify water and remove any toxic and non-toxic

materials or chemicals from it.

- These plants are used by all companies for environment protection.

- ETP's use operations like screening, sedimentation, clarification, centrifuging, evaporation

with drying methods, etc. to treat wastewater.

APPLICATION AREAS:

- Steel industry , Power industry, Textile industry, Paint industry, Distillery industry, Electroplating industry, Dairy industry, Sugar industry, Paper & Pulp industry, Oil refineries, Glass industry, Pharmaceutical

industry, Food Processing industry, Cement industry, Chlor Alkali industry, Fertilizer industry.

Waste water Treatment with Zero Liquid Discharge

- Zero liquid discharge (ZLD) is a strategic wastewater management system that ensures that

there will be no discharge of industrial wastewater into the environment.

- It is achieved by treating wastewater through recycling and then recovery and reuse for

industrial purpose.

- Hence ZLD is a cycle of closed loop with no discharge.

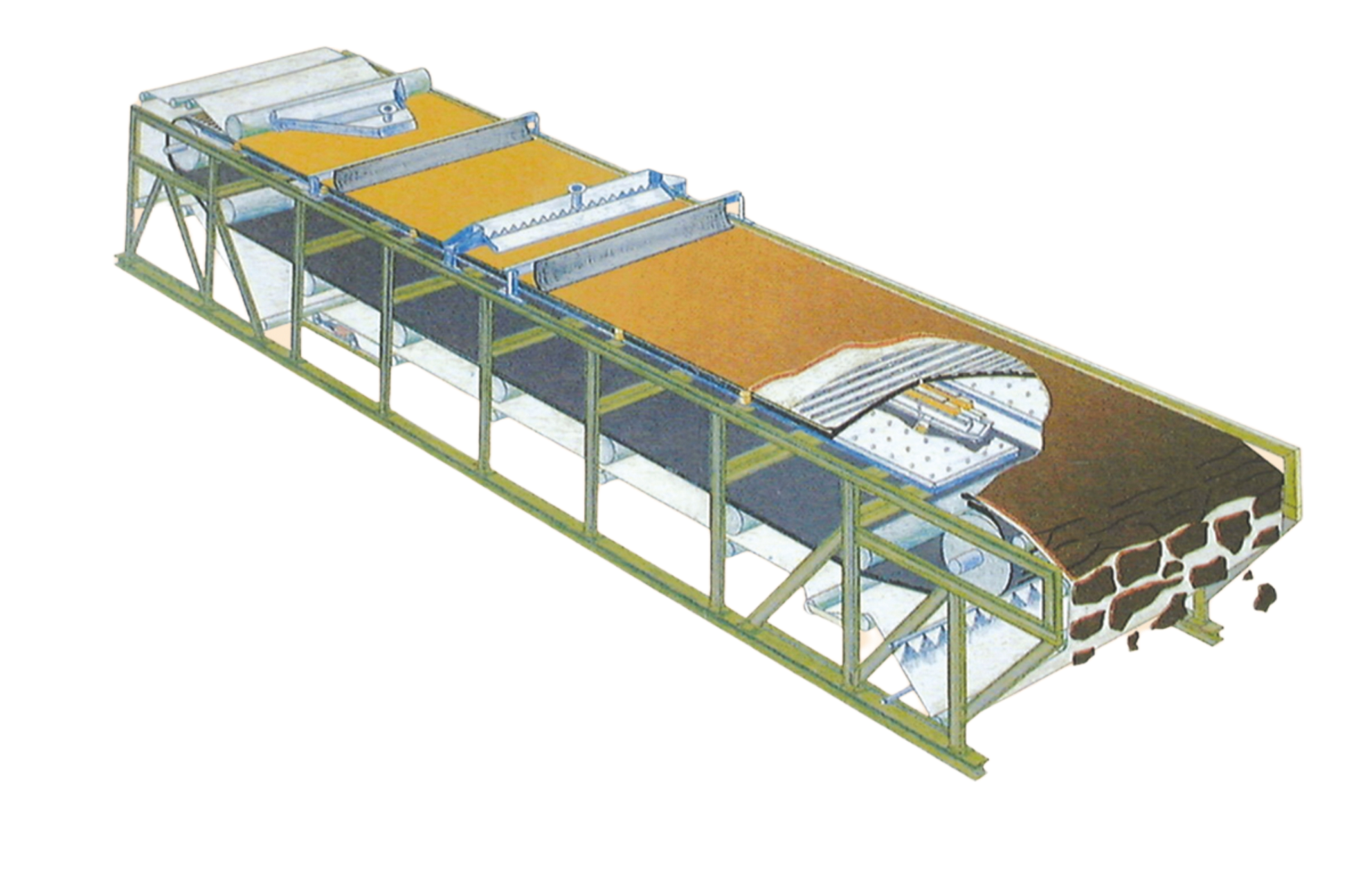

3. Horizontal Vacuum Belt Filters

Horizontal Vacuum Belt Filters

- Used for filtration of slurry in Power, Steel, Mineral Beneficiary, Fertiliser, Chemical, Paper, Sugar,

Cement, etc. Industries

- Replaces Conventional Rotary Drum Filters and Tilting Pan Filters

Advantages:

- Higher productivity per unit area.

- Offers Drier Cake.

- Easy to maintain

Savings:

- Users have reported recovery of Capital Cost in less than a year, due to increased yield and

zero out of service time.

4. Raw water intake system

OTOKLIN offers a complete range of screening equipment for Raw Water

intakes and pumping stations.

- large debris removal

- screening

- fine screening

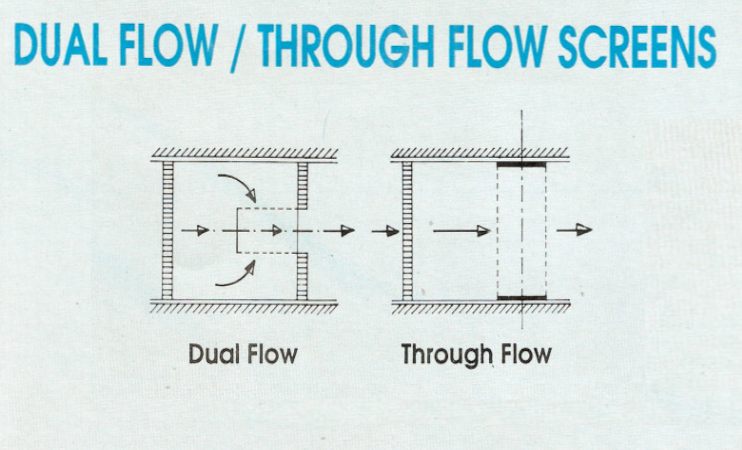

Travelling Band Screens:

These equipments are Installed in raw water gravity channels with

varying water levels, and located upstream to pumps. Both Through Flow and Dual Flow screens can

be provided.

- Flow rate - 90 to 72,000 m³/hr

- Mesh Size - 0.6 to 10 mm

- Type : -

- N

- NCA/NCB

- NCC

- depending on criticality

Bar screens with Automatic Trash Rakes

These equipments are Installed In raw water gravity channels.

They retain and remove the Trash automatically by means of differential pressure switches

actuating the cleaning rakes.

- Width 1.2 to 5 metres

- Flow rate 2,500 to 54,000 m²/hr

- Space between bars 10 to 100 mm

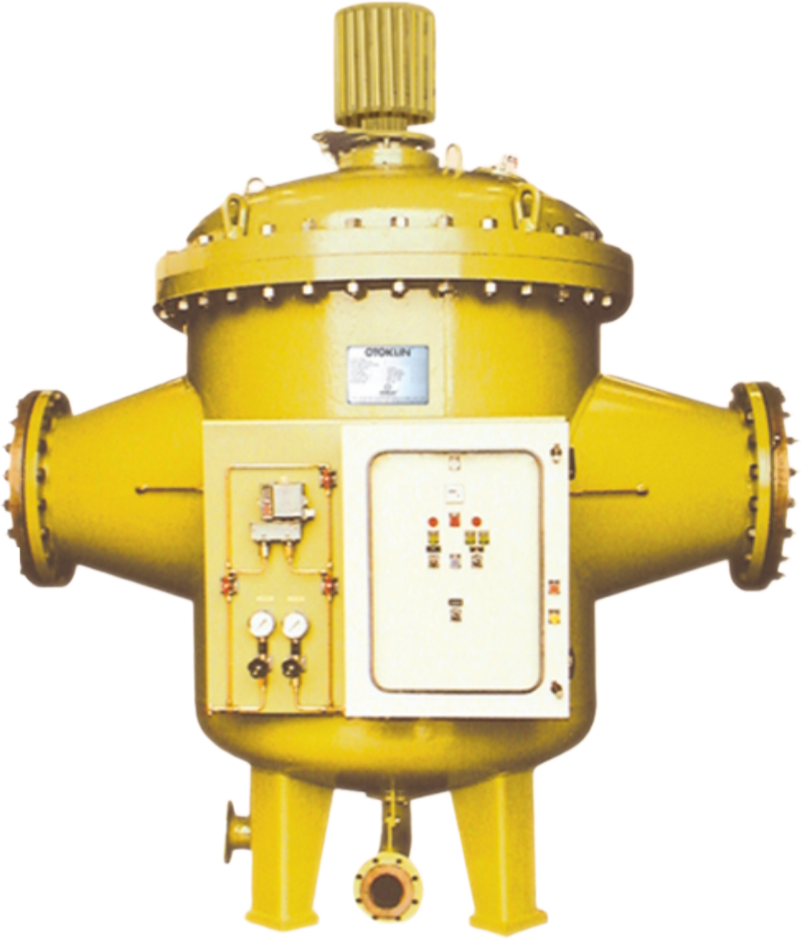

Automatic Backflushing Filter

- Used for straining raw water, clarified water, etc.

- Used in Power Plants, Steel Plants, etc.

- Also known as Debris Filter.

- Flow: Upto 6600 m³/hr.

- Filtration : 25 Micron to 5 mm.

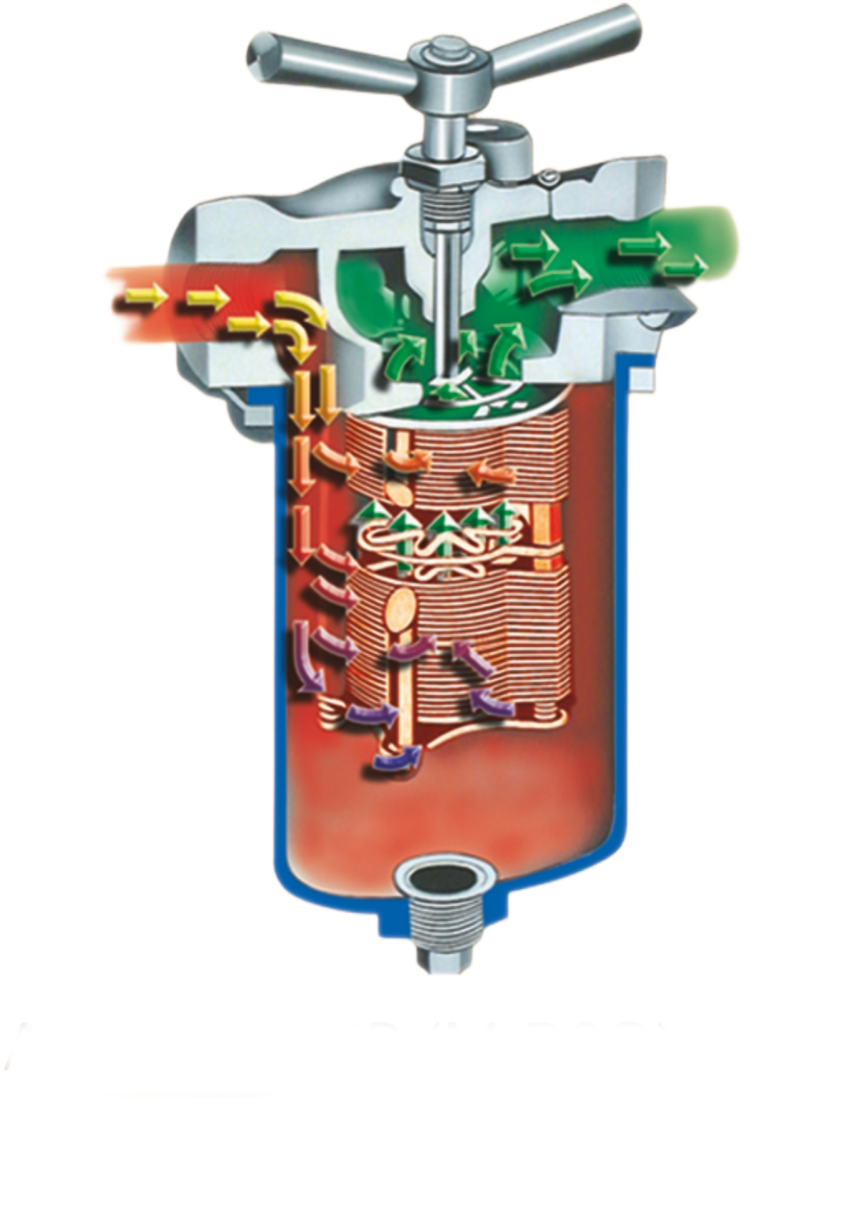

Self Cleaning Filter

- A unique filter for liquids. Just turn handle and filter is cleaned.

- Available in wide range.

- Most ideal for Fuel oil, Lube oil, Grease, Crude oil, Molasses, Rubber, Hydrocarbon oil,

Emulsions, etc.

- Flow: Upto 180 m³/hr.

- Filtration: 25 Micron to 5 mm.

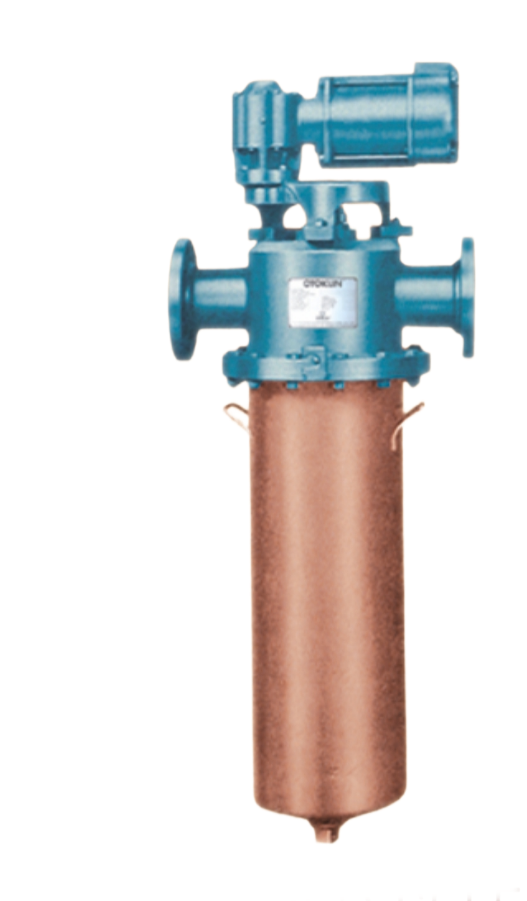

Motorised Self Cleaning Filter

- Used for filtration of Viscous liquids such as Paints, Grease, Toothpaste, Coating

solutions, etc.

- Also used for lubricating oil systems of Rolling Mills, Turbines, Heavy Machineries, etc.

- Flow: Upto 180 m³/hr.

- Filtration : 25 Micron to 5 mm.

6. Strainers & Cartridge Filters

Basket Strainers

- Uses one or more baskets in one housing.

- Baskets normally made from perforated sheets and wire mesh.

- Housing: Carbon Steel, Stainless Steel (fabricated). Cast Iron, Cast Steel, etc. with or

without lining.

- Element: Stainless Steel, Monel etc. • Size: Upto NB 600.

- Filtration: Upto 10 micron.

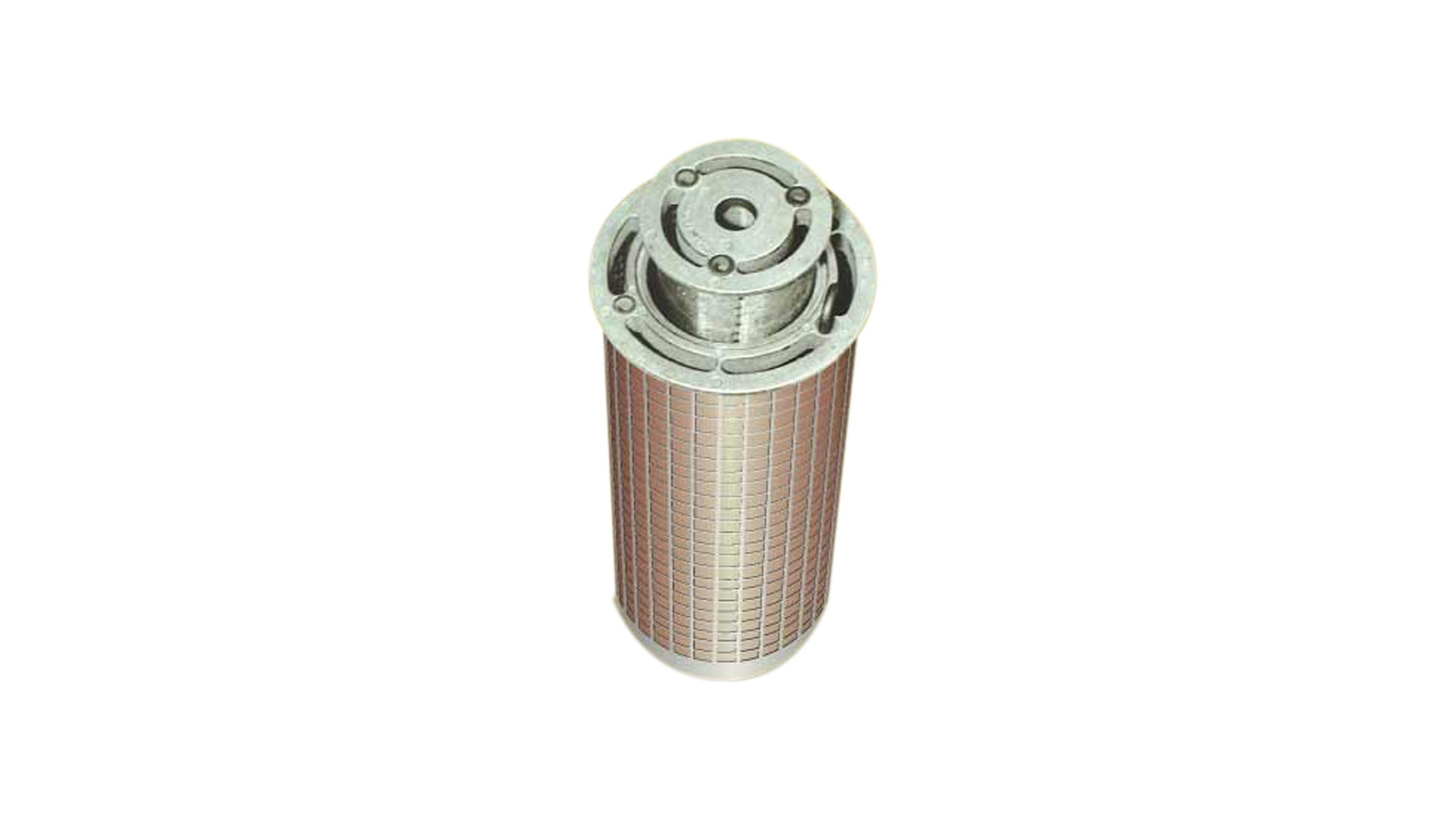

Multi Seive Baskets

Depending upon flow rate, pressure drop and degree of filtration,

surface area of filtration is increased by providing large nos. of sieves in parallel.

Cartrige Filters and Filter Elements

- Made from Fibre Glass, Nylon, Polypropylene, Cotton, Paper, Fuller's Earth, Activated

Carbon, etc.

- Suitable for filtration upto 0.2 micron.

- Filter Elements made from paper, wiremesh, fibre, cloth, etc. are made to suit customer's

specifications, samples and drawings for various plant equipments and machineries.

TEE and Y Strainers

- Made from Carbon Steel, Stainless Steel and Low Alloy Steels.

- Size: Upto NB 600.

- Rating: Upto 3000 class ANSI rating.

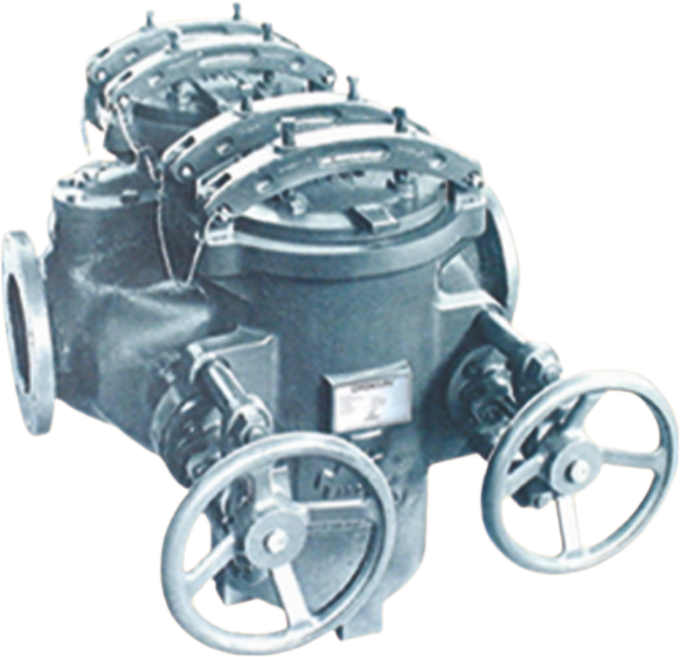

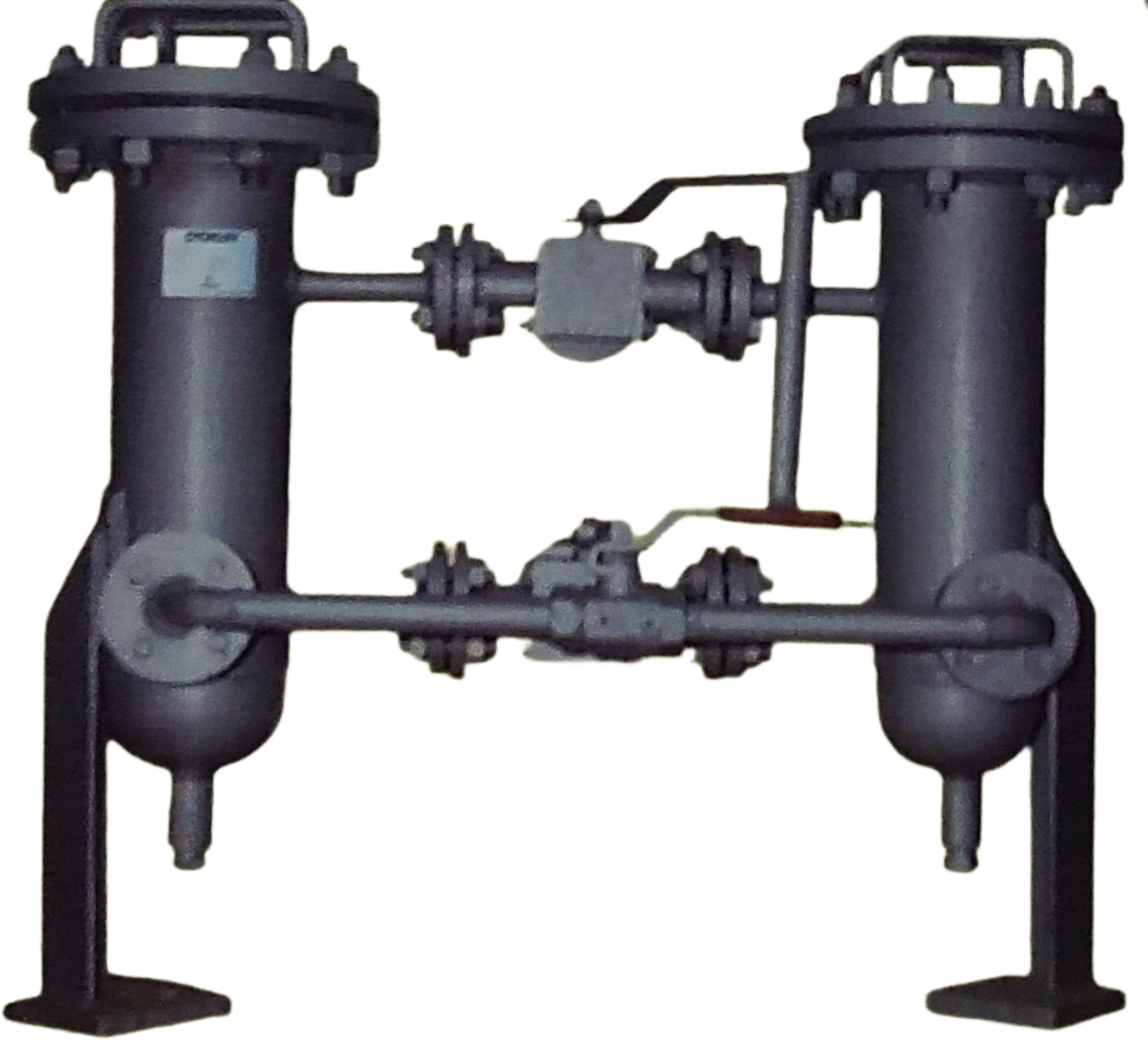

Duplex Basket Strainers

- Illustration shows strainer made from one piece housing construction.

- Housing made from cast iron, cast steel, etc.with or without rubber lining.

- Also provided with Valve Actuator, DP Switch, DP Gauge and Control Panel.

- Size: As per customer's requirments.

Duplex Strainers

- Uses six port transfer valves.

- Flow diverted from one to another strainer simply by turning handle provided on top.

- Very easy to operate.

- Size: As per customer's requirments.

Duplex Filters

- Uses 2 Nos. 3-Way Ball valves or 4 Nos. Butterfly valves.

- Housing: Carbon Steel, Stainless Steel, etc.

- Element: Brass, Stainless Steel, Monel, etc.

- Filtration: Upto 3 micron. • Pressure: Upto 2500 class ANSI rating.

- Size: As per customer's requirments.